- Home

- About Us

- Products

- Category Wise

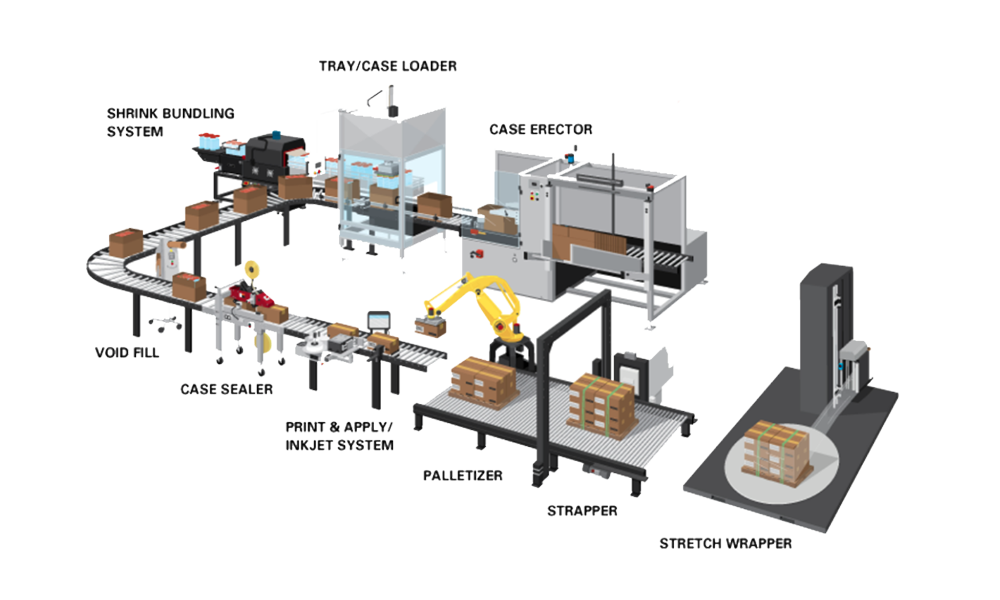

- Packaging Machineries

- Box Strapping Machine

- Stretch Wrapping Machine

- Sleeve Wrapping Machine

- Filing & Sealing Machine Manufacturer

- FFS Machine

- Granule Filling Machine

- Single Head Liquid Filling Machine

- Single Head Paste Filling Machine

- Weigh Filling Machine

- Paste Filling Machine

- Double Head Liquid Filling Machine

- Double Head Paste Filling Machine

- Mini Powder Filling Machine Manufacturer

- Powder Filling Machine

- Liquid filling Machine

- Carton Sealing Machine

- Shrink wrapping Machine

- Continuous Band Sealing Machine

- Batch Coding Machine

- Vacuum Packaging Machine

- Vertical Chamber Vacuum Packaging Machine

- Vacuum Packaging Machine (Table Top)

- Single Chamber Trolley (Economy Series)

- Single Chamber Trolley (Heavy Duty Series)

- Single Chamber Trolley ( Deep Chamber)

- Double Chamber Trolley (Economy Series)

- Double Chamber Trolley (Heavy Duty Series)

- Vertical Door Type Vacuum Packaging Machine

- MAP Tray Sealer

- Vacuum Tray Sealer Machine

- Double Chamber Trolley ( Deep Chamber)

- Vertical Models (Vertical Chamber)

- Horizontal Models (Horizontal Sealer)

- Indigenous VPM

- Packaging Materials

- Packaging Tools Manufacturer

- Spare Parts Manufacturer

- Material Handling Equipment

- Semi Electric Stacker Manufacturer

- Continuous Induction Sealing Machine Manufacturer

- Pallet Truck Manufacturer

- Hydraulic Stacker Manufacturer

- Table Truck Manufacturer

- Drum Truck Manufacturer

- Automatic Batch Coding Machine Manufacturer

- Manual Batch Coding Machine Manufacturer

- L Sealer Tunnel Combo Manufacturer

- Drum Stacker Manufacturer

- L Sealer Manual Manufacturer

- L Sealer Auto Feed Manufacturer

- Packaging Machineries

- Industry Wise

- Category Wise

- Service

- Testimonials

- Blog

- Career

- Contact Us

Menu