- Home

- About Us

- Products

- Category Wise

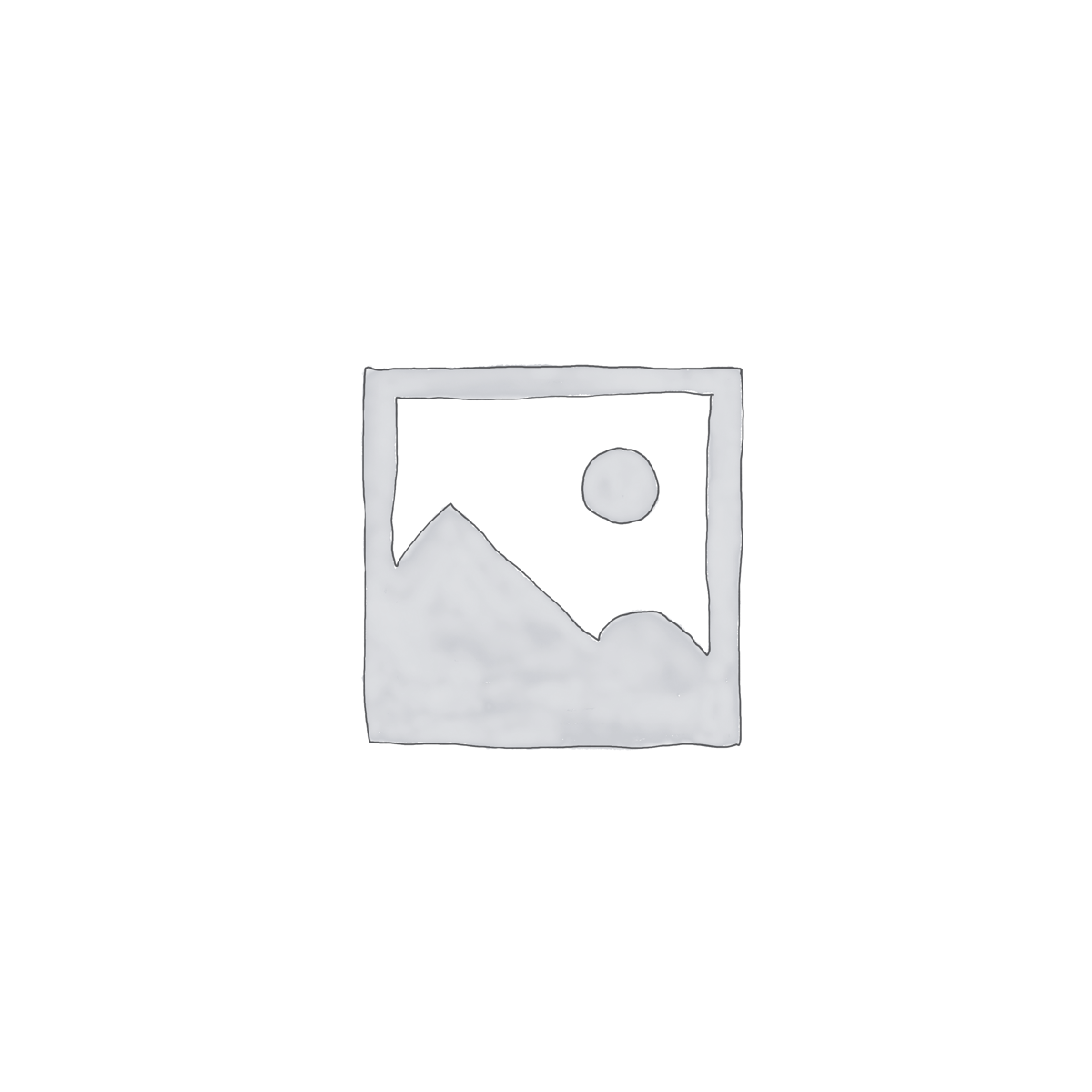

- Packaging Machineries

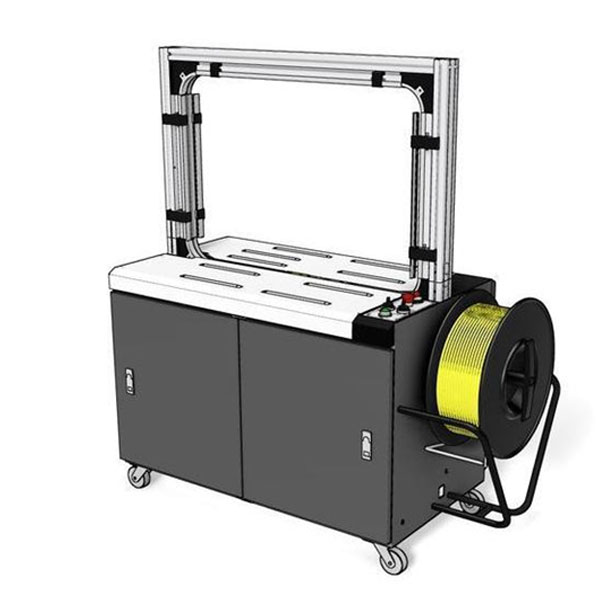

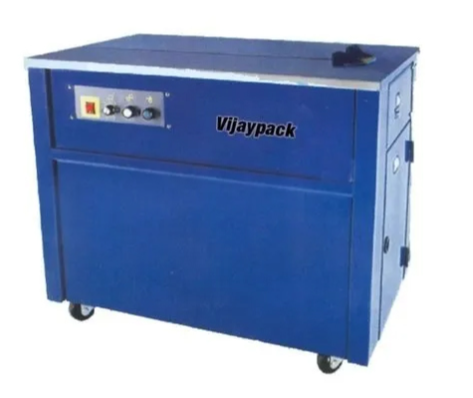

- Box Strapping Machine

- Stretch Wrapping Machine

- Sleeve Wrapping Machine

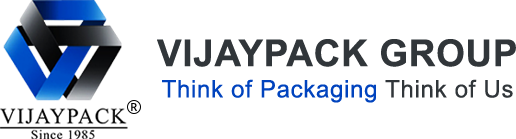

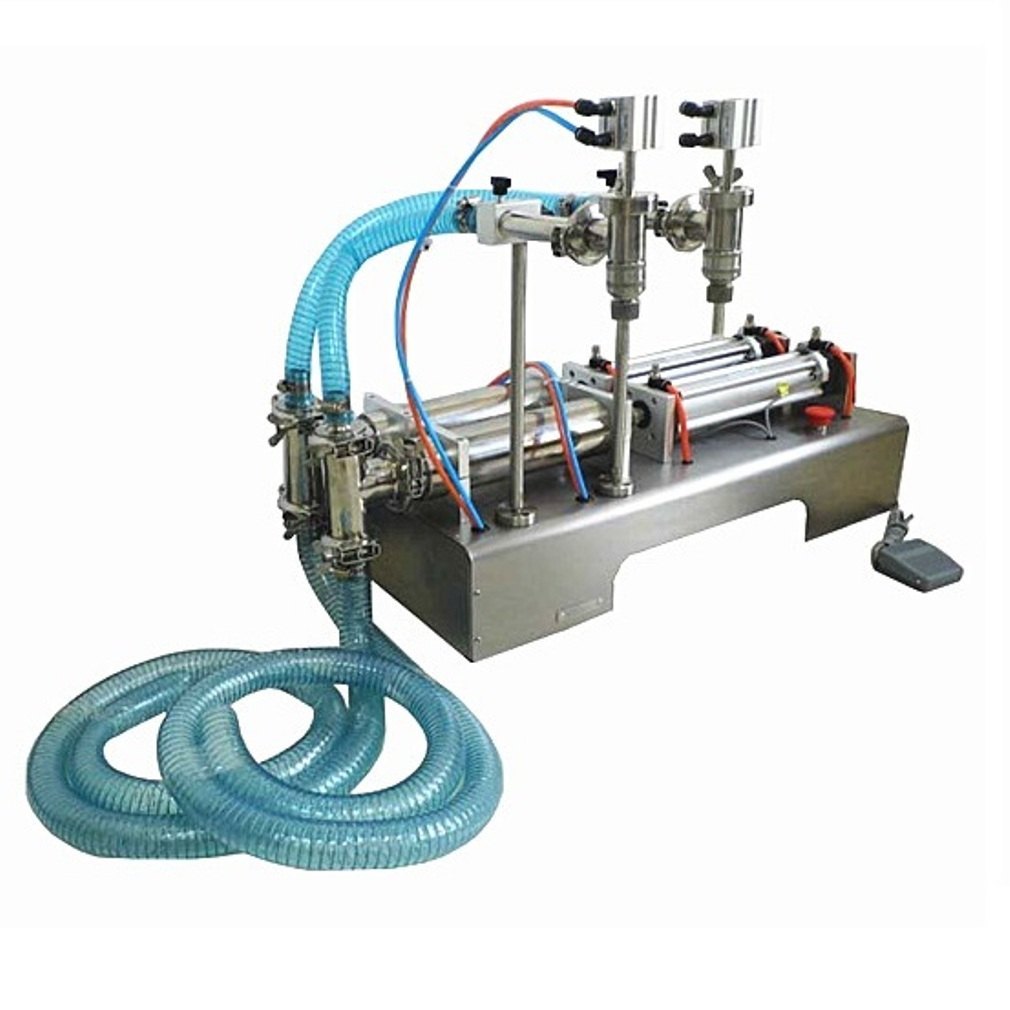

- Filing & Sealing Machine

- Carton Sealing Machine

- Shrink wrapping Machine

- Continuous Band Sealing Machine

- Vacuum Packaging Machine

- Vacuum Packaging Machine (Table Top)

- Single Chamber Trolley (Economy Series)

- Single Chamber Trolley (Heavy Duty Series)

- Single Chamber Trolley ( Deep Chamber)

- Double Chamber Trolley (Economy Series)

- Double Chamber Trolley (Heavy Duty Series)

- Double Chamber Trolley ( Deep Chamber)

- Vertical Models (Vertical Chamber)

- Horizontal Models (Horizontal Sealer)

- Indigenous VPM

- Packaging Materials

- Packaging Tools

- Spare Parts

- Packaging Machineries

- Industry Wise

- Category Wise

- Testimonials

- Career

- Contact Us

Menu